RECOMMENDED BOMBARDING PROCEDURE

(Internal

bombarding method)

©

COPYRIGHT 2006 Mark A. Snyder/SVP Neon Equipment

FOREWORD

Proper processing is essential to consistently obtain high quality,

long life luminous tubing. To accomplish this requires specific

equipment and an established procedure. The ‘bare bones’ pumping

system of days gone by, which consisted of a greased stopcock

manifold, 30-year-old 25 L/min. vacuum pump, 7.5 kva 15,000 volt

bombarder capable of only 650 mA. and using newspaper as a

“temperature gauge”, never produced consistent results – and it never

will. Add to this the seat-of-the-pants approach without any

instruments other than an oil or mercury manometer (instruments that

would otherwise give the technician information and control over the

operating parameters) and the procedure automatically became guesswork

at best.

The procedure described herein will provide a sound,

controlled approach to processing and allow the processing technician

to obtain consistent, repeatable results and the ability to produce

top quality tubes that will give years of trouble free operation.

EQUIPMENT

For this website version of our Recommended Bombarding Procedure it

will be assumed that one of our equipment packages is being used with

an appropriately sized bombarder and matching choke. Information on

each individual piece of equipment, such as manifolds, vacuum pumps,

the various instruments, etc., may be found elsewhere on this website.

GENERAL BOMBARDING PROCEDURE

It must be understood that the bombarding procedure is not an exacting

science. There are many variables to consider such as tubing diameter

and length, coated or un-coated tubing (and if coated, which coating),

electrode manufacturer and type of emission coating, size of

electrodes, number of bends in a unit, moisture content, etc. However,

there are certain parameters that must be followed in order to obtain

the desired results. Therefore, the following procedure should be

considered a guideline, but one that establishes these parameters.

For the procedure basis I will use the example of a 15mm diameter

tube, with 8 feet of glass (not including the electrodes) and coated

6500 white with 15mm, 80mA electrodes. In this case one electrode will

be a tubulated electrode. It will be found that when following this

procedure, using a tubulated electrode on one end will produce the

same consistent results as using two non-tubulated electrodes with a

side tubulation attached to the unit. Further, if the glass worker

prefers to side tubulate the unit, as some do and as is necessary

sometimes, it will also be found that it is not necessary to do so in

the middle of the unit to achieve even heating of the electrodes and

glass, provided a properly constructed and manufactured electrode is

used. Electrodes that heat inconsistently and/or unevenly are more a

function of the electrode rather than the procedure used.

STEP 1

To begin, the vacuum gauge should be turned off and the stopcock

leading to it should be closed. This will isolate the gauge tube

(sensor) from an inrush of air that would otherwise temporarily

contaminate the gauge tube. Although this will not permanently damage

it, it will require a considerable amount of time to degas before an

accurate reading can be expected. Vent the manifold to atmosphere by

slowly opening the air vent/blow hose stopcock. Attach the unit(s) to

be processed to the manifold.

RECOMMENDATION: Do not use rubber, vinyl or Teflon tubing, etc. for

this purpose. These materials exhibit tremendous outgassing properties

and some produce a phenomenon known as molecular permeation. Because

of this phenomenon, the material will never stop outgassing no mater

how long it is pumped and satisfactory vacuum levels may never be

realized.

STEP 2

Close the air vent stopcock and slowly open the main stopcock

completely. Allow the tube to evacuate for 20~30 seconds.

STEP 3

During STEP 2, connect the bombarder leads to the electrodes, and the

temperature gauge lead to the neon unit.

NOTE: The temperature gauge lead should be attached at least 6" to 8"

from either electrode but does not have to be in the middle of the

unit. Our tests have shown that the unit will heat quite evenly along

its entire length with the exception of tight bends and the glass

jacket surrounding the metal electrode shells.

CAUTION!

Check to make sure that the vacuum gauge is turned OFF and the

STOPCOCK for it IS CLOSED.

Set the bombarder choke control to the minimum setting, preferably

~150 mA.

STEP 4

Close the U-gauge stopcock. Using the air vent stopcock, admit 3~4mm

of air into the manifold as indicated by the pressure scale on the

U-gauge. This can easily be done by placing your index finger over the

open end of the side arm of the air vent stopcock. Opening and closing

the stopcock will allow a small amount of air into the manifold. It

may be necessary to repeat the procedure a couple of times to get the

desired pressure.

Bombard the tube using 150-200 mA of current until a glass temperature

of 100ºC is reached as indicated by the temperature gauge. Do not

allow the pressure to rise above 4~5mm. (If manifold pressure reaches

5mm before the glass temperature reaches 100ºC, turn off the bombarder

and reduce the pressure to 3mm by slowly opening and closing the main

stopcock, then begin bombarding again until 100ºC is reached before

proceeding.)

Turn off the bombarder and open the main stopcock completely. Let the

tube pump down for 30~60 seconds, depending on the overall size of the

unit (diameter x length), in this case (15mm single coated tube 8 ft.

long) about 30 seconds is sufficient.

WARNING! WHENEVER THE MAIN STOPCOCK IS GOING TO BE OPENED (for

whatever reason) THE BOMBARDER MUST BE OFF! FAILURE TO DO THIS CAN

RESULT IN A BOMBARDER FLASHBACK (DISCHARGE) THROUGH THE MANIFOLD AND

MAIN STOPCOCK. THIS IS VERY DANGEROUS AND CAN ALSO DAMAGE MANIFOLD AND

DIFFUSION PUMP COMPONENTS.

THIS IS VERY IMPORTANT! ALWAYS TURN OFF THE BOMBARDER BEFORE OPENING

THE MAIN STOPCOCK!

This “pre heat” procedure eliminates excessive moisture in the tube

that develops from storing the glass and during bending and splicing.

It is especially helpful when processing fluorescent blues and whites.

It removes the moisture that often causes premature discoloration in

coated tubes during bombarding. Although not entirely necessary, it

also helps in processing clear red tubes by reducing the chance of

dark spots developing and the metal electrode shell oxidizing during

the intense heating period at the end of the bombarding procedure.

STEP 5

Following the pre-heat and pre-evacuation procedure, close the main

stopcock and U-gauge stopcock. Using the air vent stopcock, admit 2mm

of air into the manifold as indicated by the pressure scale on the

U-gauge.

The length and diameter of the tube being processed and the capacity

of the bombarder usually determine the amount of pressure used to

begin bombarding. For example, a 10mm tube less than 4 feet long

should have an initial bombarding pressure of ~1mm. This is so the

glass will not overheat before the electrodes start to get hot. On the

other hand, a 15mm tube 12 feet long should have an initial pressure

of ~3mm if possible. This is determined by whether or not your

particular bombarder can light up a tube this large with this much

pressure in it. In our example we will use an initial pressure of 2mm.

NOTE: For proper bombarding the glass should get hot first and then

the electrodes. If the electrodes become red hot before the glass

reaches a temperature of at least 175ºC, the contaminants released

from the electrodes may deposit themselves on the cooler surface of

the glass. As the glass gets hotter some of the contaminants may cause

discoloration in fluorescent tubes as they are burned off the surface

of the fluorescent powder, thereby leaving dark spots and/or residue.

The discoloration may or may not get worse over time.

STEP 6:

After establishing the correct pressure, leave the U-gauge stopcock

closed in order to monitor the pressure inside the manifold while

processing the tube. Turn the bombarder on and adjust the current to

~200 mA. Continue to bombard until the glass temperature reaches

~150ºC as indicated by the temperature gauge.

It is necessary to monitor the pressure inside the manifold as

indicated by the U-gauge scale. As the glass becomes hotter the

pressure will begin to increase due to gases and vapors being released

from the surface of the glass and electrodes. In this example, any

time the pressure increases to more than 1-2mm above the initial

setting (up to 3-4mm), reduce the pressure to the initial setting of

2mm by slightly opening the main stopcock (with the bombarder off)

until the initial pressure is again obtained.

STEP 7:

At 150ºC adjust the pressure back to 2mm if necessary and increase the

current to 300 mA. (If smaller tubing is being processed, such as

12mm, it may not be necessary to increase the current at this point).

Remember to maintain the correct pressure range while proceeding.

STEP 8:

Continue to bombard until the glass temperature reaches ~200ºC. Reduce

the pressure to 2mm and increase the current to 400 mA and continue

bombarding. (On smaller diameter tubing reduce the pressure to 2mm and

increase the current to 250-300 mA).

The electrodes should now be getting hotter - a dull red-orange color

- and the glass will continue to increase in temperature.

STEP 9:

Maintain 2-3mm of pressure until the glass temperature is ~250ºC. At

250ºC reduce the pressure to 1 ½ to 2mm and increase the current to

10-15 times the electrode current rating. For example, for an 80 mA

electrode increase current to 800-1,200 mA. For a 30 mA electrode

increase current to 300-450 mA, etc. For our example increase current

to 800-850 mA.

NOTE: The maximum allowable current recommended by the electrode

manufacturer should be used if it is provided with the electrodes.

STEP 10:

Continue to bombard at 1 ½ to 2mm pressure at the maximum current for

the particular electrode used (in our case, 800-850 mA) until the

entire metal shell of the electrode is a bright, incandescent, almost

translucent, light shade of orange (sort of an illuminated pumpkin

orange) the entire length of the shell. This is very important! Electrodes that are not completely processed

will cause discoloration

in mercury tubes and cause red tubes to go dead prematurely. Depending

on electrode size, this final heating of the electrodes may take 10-20

seconds. However, it should be done in the shortest time possible

without excessive current to achieve the desired results.

If applied for too long of a time period, the high currents used for

processing the electrodes may damage the electrodes by sputtering

them. These high currents may also damage the stability of the

fluorescent powder causing decreased light output and premature

discoloration in mercury tubes.

By the time the electrodes are completely processed the glass

temperature should be

275-300ºC. However, care should be taken that the glass temperature

does not exceed ~310ºC.

NOTE: As a rule of thumb to determine whether or not the electrodes

were heated to a high enough temperature (technically ~1,200ºC), they

should exhibit some visible glow (though diminishing as the electrodes

begin to cool) for 15-20 seconds after the bombarder is turned off. If

they cannot do this, they were probably not heated to a high enough

temperature.

STEP 11:

Turn the bombarder off and completely open the main stopcock to

evacuate the tube. Open the U-gauge stopcock. Turn on the vacuum

gauge, but wait a few moments (~10 seconds) before opening the vacuum

gauge stopcock.

NOTE: With O-ring type stopcocks, “completely open” means to unscrew

and retract the white Teflon stopcock plug from the glass barrel as

far as possible without the upper most O-ring loosing its seal inside

the glass barrel.

STEP 12:

Immediately following Step 11, gently but thoroughly heat the

tubulation glass with the tipping torch between the neon unit and the

manifold with special attention given to the area where the final

seal-off will be made. However, if it is a mercury unit do not heat

the trap bubble that contains the mercury; heat the tubulation to

within ~½” of the bubble.

This step is done for several reasons: To prevent contaminant gases

that are being pumped out of the neon unit from condensing on an

otherwise cold tubulation, to burn off impurities that are present on

the interior surface of the tubulation glass, which would otherwise be

liberated when the final seal-off is made, and to prevent the mercury

from picking up contaminants as it is rolled through the tubulation

into the neon unit.

STEP 13:

While the unit is being evacuated, unhook the bombarder leads from the

electrodes and monitor both the temperature gauge and vacuum gauge to

confirm that the following minimum pump down criteria is met:

• By the time the glass cools to 200°C the pressure should be below 10

µ (microns).

• By the time the glass cools to 175°C the pressure should be below 5

µ.

• By the time the glass cools to 150°C the pressure should be at or

below 1 µ.

• Final vacuum before filling should be 1 µ or less.

NOTE: The above pump down speeds should be considered bare minimums.

Faster pump down times should be strived for.

More satisfactory pumping speeds are:

• By the time the glass cools to 200°C the pressure should be below 5

µ.

• By the time the glass cools to 175°C the pressure should be below 1

µ.

• By the time the glass cools to 150°C the pressure should be below

0.5 µ.

• Final vacuum before filling should be below 0.5 µ, but preferably

0.1 µ or less.

CAUTION!

Do not “flash” the bombarder to check for adequate vacuum. This can

damage the electrodes, the emission coating inside the electrodes and

the fluorescent powder. The damage may not be evident until the unit

has been in service for some time. “Flashing” the bombarder to check

for adequate vacuum may also cause a bombarder flashback through the

manifold, which may damage manifold and vacuum pump components.

STEP 14:

When the tube has cooled to 70-80°C, and the pumping

speed criteria has been met and a vacuum of 1 micron or less

(preferably less) has been obtained, the unit is ready for filling:

• Remove the temperature gauge lead.

• Close the vacuum gauge stopcock and turn the vacuum gauge off.

• Close the main stopcock.

• Close the U-gauge stopcock.

• Fill the unit with the desired gas to the correct pressure for the

size of tubing used.

• Immediately OPEN the U-gauge stopcock.

• Seal the unit off from the manifold.

AGING:

The finished unit should be ‘aged’ or ‘burned-in’ at 1½ - 2 times the

normal operating current of the electrodes used. For example, 30 mA

electrodes should be aged at 45-60 mA and 60 mA electrodes aged at

90-120 mA, etc.

Units filled with red gas should be the correct color immediately, but

should never take more than a few minutes to come up to full color.

Mercury units should be run for a few minutes before the mercury is

inserted to examine gas color, electrode firing, to insure a stable

discharge and to clean up any residue impurities. After this is done,

turn the unit off and allow the electrodes to cool. Insert the mercury

and roll the mercury from one electrode to the other, making sure some

mercury sticks to each electrode. Make the final seal-off of the

tubulation and age the unit by running it at the previously stated

burn-in currents until the mercury has vaporized throughout the entire

length of the unit and it is up to full color.

AGING CURRENT:

There will undoubtedly be some disagreement with the listed

recommendations. However, electrode manufacturers commonly use

excessive currents to do accelerated life tests on electrodes. They

have found that a properly processed tube should be able to operate at

3 to 4 times the normal operating current for several hours with no

adverse effects to the glass or electrodes. If a unit cannot do this

it simply was not processed correctly and/or inferior materials were

used to fabricate the unit.

PUMPING SPEEDS & FLUSHING:

If the pumping speeds listed previously are obtained it should not be

necessary to use any type of flushing gas or procedure. However, if a

flushing procedure is desired a simple additional step that can

further “clean” the tube follows:

After bombarding is complete and the unit has cooled to ~200°C and

there is absolutely no glow to the electrodes, admit a few millimeters

of neon gas into the tube and evacuate immediately.

The theory is that once a certain level of vacuum has been reached,

say 1 micron (1x10-3 Torr), all the remaining molecules of gas in the

tube are impurities, such as water vapor, carbon dioxide, etc. If an

inert gas such as neon is introduced, and the pressure is again

reduced to 1 micron, 50% of the remaining gas inside the tube will now

be neon gas and the other 50% impure gas. Therefore, the remaining

impure gas has been reduced by half. (Specifically, at a pressure of 1

micron there are 40 trillion molecules of gas left in every cubic

centimeter of ‘space’).

Actually, the end results are slightly more favorable than this

because the more common gases are pumped out more easily, thereby

leaving a higher percentage of inert gas as part of the remaining gas

load. The remaining inert gas will obviously not affect the operation

of the tube.

When performing this step always remember to close the vacuum gauge

stopcock before flushing. Exposing the gauge tube to inert gas will

not permanently harm the gauge tube, but it will require a period of

time to degas before accurate readings can be obtained.

COMMENTS:

Bombarding is a procedure that should not be rushed. A slow, gentle

approach will be found to be more effective than a fast, intense one

in terms of maximum light output, electrode life and the elimination

of contaminants that would otherwise effect the operation of the tube.

For example, if a piece of tubing is sustained at a temperature of

200°C for a period of 2 minutes, more impurities will be liberated

than if the same temperature were sustained for only a few seconds. As

well, if the electrodes are heated gradually the metal will be more

thoroughly degassed and the emission coating will be more completely

converted than if the procedure were rushed. Moreover, a slow ‘cook’

time is more desirable than a fast one.

Relative to processing the electrodes, a heating time of 5 to 6

minutes (depending on the particular electrode) with a final shell

temperature of 1,000°C will result in a shell that is roughly 90%

degassed. The shorter the bombarding time, the less the shell will be

degassed. At a bombarding time of 2 minutes and a shell temperature of

650°C (dull, dark red) the shell is only ~45% degassed. Generally

speaking, the less that the shells are heated and degassed, the less

the emission coating is processed and converted. Emission coating that

is not processed and converted will gradually contaminate the tube

over a period of time causing discoloration and tube failure.

I have visited shops where the ‘pumper’ tries to bombard units as fast

as possible, then have to let the unit pump down for 3-4 minutes in an

attempt to obtain a satisfactory vacuum as determined by ‘flashing’

the bombarder. The overall processing time for the unit ends up taking

at least 5-6 minutes, mainly due to the length of time required

attempting to outgas improperly heated glass and electrodes, with the

end results being unsatisfactory.

The procedure herein will take 4 to 5 minutes when processing coated

tubing and in the end will yield superior results. In the case of red

tubes pumping times can be reduced considerably by filling tubes ‘hot,

often at 150°C and even 175°C, provided the appropriate vacuum levels

are obtained before filling and the filling pressure is adjusted

accordingly.

|

TUBE PROCESSING QUICK

REFERENCE CHART |

|

FOR AVERAGE SIZE UNITS |

|

(15mm, ~8 feet long) |

|

|

|

|

|

|

BOMBARDING |

|

|

|

|

|

|

GLASS TEMPERATURE |

PRESSURE |

CURRENT |

|

|

UP TO 150°C |

2 – 4 mm |

200 mA |

|

|

150 - 200°C |

2 – 4 mm |

300 mA |

|

|

200 - 250°C |

2 – 4 mm |

400 mA |

|

|

250 - 300°C |

1 1/2 – 2 mm |

800 mA

or maximum

allowed for

electrodes used (10-15 x rating) |

|

|

|

|

|

|

|

PUMPING |

|

|

|

|

|

|

GLASS COOL DOWN |

|

VACUUM OBTAINED |

|

|

TEMPERATURE |

|

IN MICRONS |

|

|

|

|

|

|

|

|

|

GOOD

BETTER |

|

|

200°C |

|

- - -

< 10 |

|

|

175°C |

|

< 10

< 5 |

|

|

150°C |

|

<

5

< 1 |

|

|

75°C |

|

<

1

< 0.1 |

|

|

|

RECOMMENDED FILLING PRESSURES

(AT 70-80°C GLASS TEMPERATURE) |

|

|

|

|

|

|

|

TUBE DIAMETER |

PRESSURE (Torr/mm Hg.)

|

|

|

|

8 mm |

........................... |

17 mm |

|

|

|

|

9

mm |

........................... |

15 mm |

|

|

|

|

10 mm |

........................... |

13 mm |

|

|

|

|

11 mm |

........................... |

12 mm |

|

|

|

|

12 mm |

........................... |

11 mm |

|

|

|

|

13 mm |

........................... |

10 mm |

|

|

|

|

15 mm |

........................... |

9 mm |

|

|

|

|

18 mm |

........................... |

8 mm |

|

|

|

|

20 mm |

........................... |

7.5 mm |

|

|

|

|

22 mm |

........................... |

7

mm |

|

|

|

|

25 mm |

........................... |

6 mm |

HP, 4 mm LP |

|

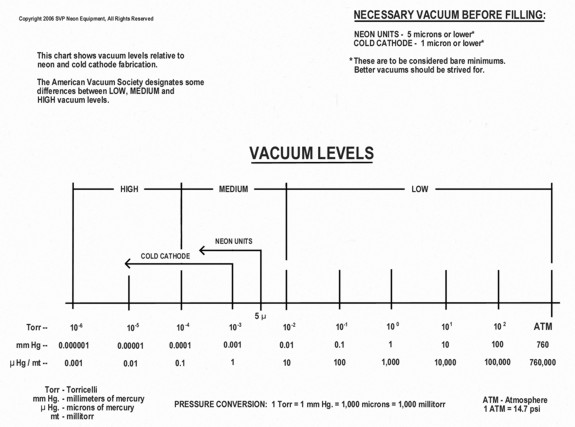

(CLICK BELOW PICTURE TO ENLARGE)

|