INSTALLING & TROUBLESHOOTING

THREADED GLASS COMPRESSION 0-RING CONNECTORS

Revised April, 2006

Copyright © 2006 SVP Neon Equipment - All Rights Reserved

The design of

borosilicate glass (Pyrex) neon manifolds and related components often

incorporates the use of various sizes of threaded glass compression

O-ring connectors, generally referred to as ‘threaded connectors’ or

‘connectors’.

From time to time equipment operators may suspect that a connector is

leaking. Therefore it is the intention of these instructions to

outline the proper installation and troubleshooting procedures

necessary to obtain and maintain a high vacuum connection when using

this particular type of connector.

INSTALLATION:

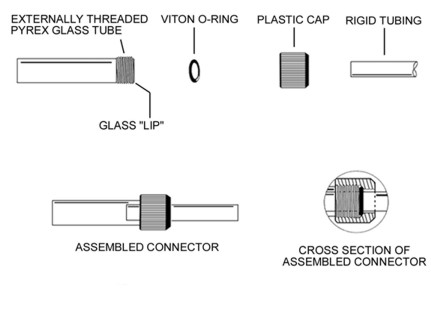

Refer to the diagram at the bottom to become familiar with the components

that comprise a connector and how these components fit together to

make a complete connection. From left to right: The Externally

Threaded Pyrex Glass Tube, the Viton O-ring and the Plastic Cap.

Furthest to the right is the tubing to be inserted through the cap and

0-ring and into the externally threaded glass tube. This tubing may be

a stopcock sidearm, debris trap arm or pumping attachment. It may also

be a metal tube from a metal needle valve used with high pressure rare

gas canisters, or any other rigid tubing.

CAUTION:

The external glass threads are precision cut and polished and are very

delicate. Bumping something hard against them such as another piece of

glass will chip the threads easily. The chipped thread may cause the

glass threads to crack when the cap is tightened if the chip is not

polished first to remove any sharp edges.

MAKE SURE HANDS ARE CLEAN BEFORE HANDLING COMPONENTS!

Make sure the O-ring, end of the glass thread (the “lip”) and rigid

tubing are perfectly clean. There should not be even a speck of dust

on them as it can create a leak path. THIS IS VERY IMPORTANT!

Most problems with leaks are the result of dirty O-rings!

STEP 1: Slide the plastic cap over whatever rigid tubing

is to be attached to the threaded connector.

STEP 2: Slide the O-ring over the rigid tubing after the

cap.

NOTE: DO NOT apply any type of lubricant to the

connector O-rings. The connectors rely on friction to function

properly. Any lubricant will defeat this purpose.

STEP 3: Pull the cap over the O-ring so that the O-ring

is completely inside the cap and against the inside beveled shoulder

of the cap.

NOTE: On some tubing/connector size combinations it

may be necessary to “work” the cap over the O-ring as some

combinations are a snug fit. This can be accomplished by sliding the

cap onto the tubing a considerable distance, sliding the O-ring up

against the cap and pulling the cap back over the O-ring until the

O-ring is all the way inside the cap. Another alternative is to use a

blunt instrument to push the O-ring inside the cap. Be careful not to

nick or puncture the O-ring or scratch the rigid tubing. The smallest

cut, pin hole or scratch will cause the connector to leak when vacuum

is applied.

STEP 4: Insert the rigid tubing into the externally

threaded glass tube and screw the plastic cap onto the glass threads

until the O-ring is seated against the beveled shoulder inside the cap

and against the ‘lip’ of the glass thread.

NOTE: On some tubing/connector size combinations it

will be necessary to continue tightening the cap until the O-ring

touches the rigid tubing around its circumference before final

tightening is done.

STEP 5: Once the O-ring is lightly seated against the

inside beveled shoulder of the cap, the lip of the glass threads and

the tube that is inserted through the cap and O-ring, continue to

tighten the cap another ¼ to ½ turn only.

CAUTION: DO NOT OVER TIGHTEN THE

CAP! DO NOT USE TOOLS TO TIGHTEN THE CAP! THE CAP SHOULD BE HAND

TIGHTENED ONLY!

STEP 6: After the connection(s) have been tightened and

they are under a hard vacuum check the tightness of the caps again to

make sure they are snug.

TROUBLESHOOTING:

If a connector is suspected of leaking there are four (4) basic steps

to follow to determine if a connection is physically undamaged and in

proper working condition. These four steps apply to any size

connector.

If the following four steps yield positive results and all components

of a connector are physically undamaged, it can be safely assumed that

the connector will achieve a high vacuum seal provided the components

of the connector are properly cleaned, assembled and tightened. When

properly cleaned, assembled, tightened and thoroughly outgassed the

connectors are capable of vacuum levels in the 10-8 Torr range, which

is well into the Ultra High Vacuum region.

WARNING! DO NOT TEST FOR LEAKS AROUND THE O-RINGS USING A TESLA

COIL (SPARK TESTER). THE DISCHARGE FROM THE SPARK TESTER WILL PUNCTURE

HOLES IN THE O-RINGS THEREBY CAUSING LEAKS AND MAKING IT DIFFICULT TO

TROUBLESHOOT A SUSPECTED CONNECTOR.

STEP 1 - CHECKING THE O-RING:

An O-ring stretching tool such as a tapered shaft of the appropriate

size should be used for this step. Disassemble the connector

completely. Make sure the O-ring is perfectly clean. Most leaks are

the result of dirty O-rings. Slide the O-ring onto the tool until the

O-ring stretches at least 25% to 30% beyond its normal size. If there

are any pin holes, nicks or cuts in the O-ring they will expand in

size and be much larger and easier to see. If an O-ring splits apart

while doing this then the O-ring had a defect in it.

Examine the entire surface of the O-ring including the inside

diameter. This can be done by “rolling” the O-ring on the tool until

the inside diameter is facing out. Examine the “face” of the O-ring,

which is the area that seals against the glass lip. These are the

critical areas that maintain the high vacuum seal. If an O-ring has

any defects or imperfections it should be replaced.

STEP 2 - CHECKING THE GLASS LIP:

With the connector disassembled, visually look at and thoroughly

inspect the very edge of the open end of the glass threads. This is

called the “lip”. This is the surface that the O-ring seals against.

The entire lip must have a very smooth fire polished surface. It must

not have any nicks, chips or even scratches in it. These will cause a

leak path past the O-ring and prevent the assembled connector from

obtaining a high vacuum.

NOTE: Minor chips in the glass threads do not affect

the O-ring seal. However, make sure any glass fragments from chipped

threads are not left in the plastic cap during assembly as this may

cause the glass to crack when the cap is tightened. Chipped threads

should either be fire polished or sanded with fine grit paper so they

are smooth and not sharp. Sharp edges may cause the glass thread to

crack when the cap is tightened.

STEP 3 - CHECKING O-RING COMPRESSION:

Examine the inside of the plastic cap, particularly in the area of the

beveled shoulder, for tooling slag, burrs or other debris. Install

only the cap and O-ring onto the glass threads. Screw the cap onto the

glass threads as far as it will go, thereby compressing the O-ring.

Look into the cap at the way the O-ring is being compressed. The

O-ring should be centered in the cap and the inside diameter of the

O-ring should compress evenly all around, 30% to 40% smaller than its

normal size. If the O-ring compresses unevenly, such as an oval or egg

shape, or is off center, it may not provide a good seal. In this case

the cap may be defective and should be replaced.

STEP 4 - CHECKING THE RIGID TUBING:

The rigid tube that is inserted into a connector is perhaps the most

overlooked potential problem area. Particular areas where problems

arise are where a glass gas flask connects to the gas flask stopcocks,

the tubulation connection and the connection between the mechanical

vacuum pump and diffusion pump and/or main stopcock, or anywhere lead

glass tubing is generally used. However, the problem can arise

anywhere a rigid tube is inserted into a connector.

The tube that is inserted into the connector must be free of any

scratches or other imperfections on its outside surface in the area

where the O-ring will make its seal around the tube. In the case of

glass tubing, the tubing should first be thoroughly cleaned and then

fire polished until the scratches are no longer visible. Care should

be used not to distort the diameter and/or circumference of the tube

from overheating it.

NOTE: Make sure glass tubing is thoroughly flame

annealed after fire polishing. If severe, remaining stress may cause

the glass tube to fracture when the O-ring is compressed around it.

Other types of rigid tubing should have scratches removed by polishing

with an appropriate method until the surface approaches the smoothness

of glass.

GENERALLY SPEAKING:

Cleanliness and meticulous attention to detail are extremely

important. Components that will be exposed to the inside of a high

vacuum system should be relatively free of finger prints and other

residue substances. If finger prints or other residue is evident on a

component that will be exposed to the inside of the vacuum system it

should be cleaned off before final assembly with a lint free cloth and

an appropriate solvent. The first choice of solvent for this purpose

is a high purity acetone with a low residue after evaporation. A

second choice is isopropyl alcohol. Lint free paper towels, such as

Bounty, are a good choice for this purpose provided they are white and

not a printed ink pattern. O-rings can be laid on a clean sheet of

white copy machine paper for final inspection before assembly.

O-RING MATERIAL & LIFE:

As with anything, there are inferior products on the market. Good

quality Viton O-rings should be used. Make sure the O-rings are first

quality Viton material. How hard or soft the material is is referred

to as the durometer. Use a number 75 durometer Viton O-ring for best

results. O-ring suppliers and manufacturers typically call these V75.

V60, V90, etc. Other durometers are also available, but V75 is the best

choice for this purpose. (Some suppliers offer V70 O-rings which is an

acceptable substitute).

Good quality V75 O-rings have been known to last more than ten (10)

years under normal use without need for replacement. If the O-ring is

less than two years old, defects are usually the result of neglect,

over tightening or some other form of abuse.

TROUBLESHOOTING

QUICK REFERENCE GUIDE

1) Check the O-ring for dirt & debris, pin holes, nicks, cuts or other

defects.

2) Check the threaded glass “lip” for scratches, nicks or chips.

3) Check for correct centering and O-ring compression with the plastic

cap.

4) Check the rigid tube for exterior scratches and other

imperfections.

5) Tighten the connector according to these instructions.

| |

|

|

| |

|

|

|

|

| |

THREADED CONNECTORS |

|

| |

|

|

|

|

| |

CONNECTOR SIZE |

ACCEPTS TUBING SIZE |

O-RING SIZE |

|

| |

#7 |

4 mm to 7 mm

(5 mm Works best) |

107 |

|

| |

#9 |

7 mm to 9 mm |

110 (or 109) |

|

| |

#15 |

12 mm to 15 mm |

206 |

|

| |

#18 |

15 mm to 19 mm |

208 |

|

| |

#25 |

22 mm to 25 mm

|

317 |

|

| |

|

|

|

|

| |

O-RING MATERIAL:

VITON

O-RING DUROMETER: 75

|

|

|

|

SVP

Neon Equipment

(Silica Vacuum Products)

113 Leventis Drive, Suite A

Columbia, South Carolina 29209

Ph. (803) 783-1165

www.svpneon.com

|

|