|

|

SVP

BOMBARDING TEMPERATURE GAUGE

| |

|

|

The SVP Bombarding

Temperature Gauge is

the only instrument of its kind on the market

specifically designed for high voltage luminous

tube processing. It is unaffected by the high

voltage electromagnetic field (corona discharge)

produced by the bombarder as are other types

of instruments and mediums.

The Simpson Self-Shielding Annular Pivot &

Spring-Loaded Jewels meter assembly is the

highest torque to weight ratio meter available.

The meter assembly is enclosed in a PVC

meter box and is completely self-powered. It

does not require batteries or other electrical

source to function.

|

|

|

The temperature

sensor is a clamp-on unit, which ensures positive contact with

the glass. The sensor is encapsulated in a heat sensitive glass

fiber material that protects the sensor from oxidation. The

thermocouple wire is sheathed in high temperature silicone

rubber tubing rated at 600°F and is 60” long. This allows

stationary placement of the instrument without having to move it

with each processing cycle. (Custom lengths are available)

The large 4½” meter face is easy to see and truly unique. It

provides the processing technician with at-a-glance information

during the heating stage as well as the glass cool- down stage -

something other gauges, crayons and paper simply cannot do.

SUMMARY:

A bombarding temperature gauge is one of the four instruments

essential for proper luminous tube processing. A specific glass

temperature is necessary to insure that the maximum amount of

contaminants and impurities are released from the internal

surface of the tubing. If allowed to remain, these impurities

will affect the life, efficiency and overall quality of the

finished unit. In red tubes excessive impurities will cause

premature failure. In mercury discharge tubes it will cause

premature and unnecessary staining and discoloration. Therefore,

a specific glass temperature allows for highly effective

degassing of the tube and at the same time ensures that the

glass is not overheated, which may damage phosphor coatings and

the glass structure.

The SVP Bombarding Temperature Gauge is unique from other

meters/gauges and methods. In addition to being unaffected by

the high voltage corona discharge produced by the bombarder as

are other instruments, crayons and mediums, the meter face has

specific markings for the heating stage that correspond with

most electrode manufacturers bombarding recommendations. The

meter face also incorporates specific markings to compare glass

cool down temperatures with the speed of evacuation* following

the bombarding cycle**. This ensures that the unit is being

evacuated at a fast enough rate compared to specific glass

temperatures to ensure that re-absorption of the contaminants

released during bombarding does not occur. (The temperature at

which re-absorption begins is approximately 175ºC as the glass

cools***.) The large 4½” analog meter face in conjunction with

these specific markings provides the processing technician with

at-a-glance information as opposed to trying to focus on rapidly

changing digital numbers during the critical stages of

processing, or guessing at what the glass temperature may be if

a temperature gauge is not used at all.

* In addition to the SVP Bombarding Temperature Gauge, a high

vacuum gauge is necessary to accomplish the

comparison between glass cool down temperatures and the vacuum

levels obtained.

** SVP Neon Equipment is the only equipment manufacturer who

recommends specific values for evacuation speed vs.

glass cool down temperature.

*** Extrapolated from a graph produced by Sherwood, Westinghouse

Electric and Manufacturing Company. |

|

|

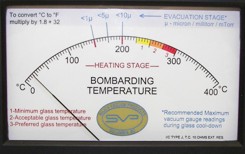

METER FACE DETAIL:

The first things you will notice in contrast to

other temperature gauges are the various

colored markings on the meter face. Each

marking has a specific meaning and purpose.

They are placed at these temperatures to

reference the designated temperatures during

various stages of the processing procedure.

Once the processing technician is familiar with

them the instrument will be invaluable in helping

the technician to produce consistent, repeatable

and reliable results, which will eliminate much of

the guesswork from the processing procedure.

|

|

|

Along the lower portion of the scale, the red lines

at 150°C and 200°C are temperatures at which

the manifold pressure and bombarding current

should be adjusted, following the guidelines

set forth in our discourse titled

Recommended Bombarding Procedure.

For the yellow, orange and red temperature ranges and corresponding

numbers there is a legend in the lower left corner of the meter face

with a short explanation of the various ranges: 1- Minimum glass

temperature; 2- Acceptable glass temperature; 3- Preferred glass

temperature.

Some of these temperatures are also points of pressure and current

adjustment while processing. These are also covered in more detail in

our Recommended Bombarding Procedure.

In

general, the yellow temperature range between 225ºC and 250ºC should

be considered a bare minimum, marginal glass temperature. The orange

temperature range between 250ºC and 275ºC is a satisfactory glass

temperature provided a fast pumping system is used and reasonable

lengths of tubing are being processed. The red temperature range

between 275ºC and 300ºC is the preferred glass temperature range for

thorough processing. The red temperature range will release more

impurities and contaminants from the interior surface of the glass and

will allow a longer evacuation period before the glass cools to the

re-absorption temperature of 175ºC.

Along the upper portion of the scale you will notice three blue lines

with symbols above them along with corresponding blue text in the

upper right corner and lower right corner. The text in the upper right

corner signifies that the blue lines and symbols to the left are for

reference during the evacuation stage. These numbers are to be

compared to the readings on a high vacuum gauge (ultimate vacuum

gauge, micron gauge, etc.) to ensure that the tube is being evacuated

at a sufficient rate of speed. The blue text in the lower right corner

indicates that these are the Recommended Maximum (worst) vacuum gauge

readings that should be obtained during glass cool down. Better vacuum

levels should be strived for. The symbol < means “less than” and the

symbol µ means “microns” (a vacuum measurement, which is the same as

mTorr or millitorr). So, the symbol <10µ directly above the 200ºC mark

means “less than 10 microns”.

For example: After the unit has been bombarded to the proper glass

temperature the bombarder is turned off. The main stopcock is fully

opened to evacuate the tube. The high vacuum gauge is turned on and

the stopcock for it is opened. The tube begins to cool as indicated by

the temperature gauge. When the needle on the temperature gauge drops

to 200ºC the level of vacuum as indicated by the vacuum gauge should

be <10µ (less than 10 microns). When the glass has cooled to 175ºC the

level of vacuum indicated by the vacuum gauge should be <5µ (less than

5 microns), etc. If these marginal vacuum levels cannot be obtained,

then the vacuum system does not evacuate quickly enough and quality

units will be impossible to produce.

|

|

|

Proudly

Made in

the USA |

|

|

|

|